Michelin View on Material

19 March 2018

Tags : kordsa,

michelin,

mobility,

performance,

product,

recycle,

reduce,

reinforcement,

reinforcer,

renewable,

reuse,

sustainability,

thereinforcer,

tire

1. Introduction

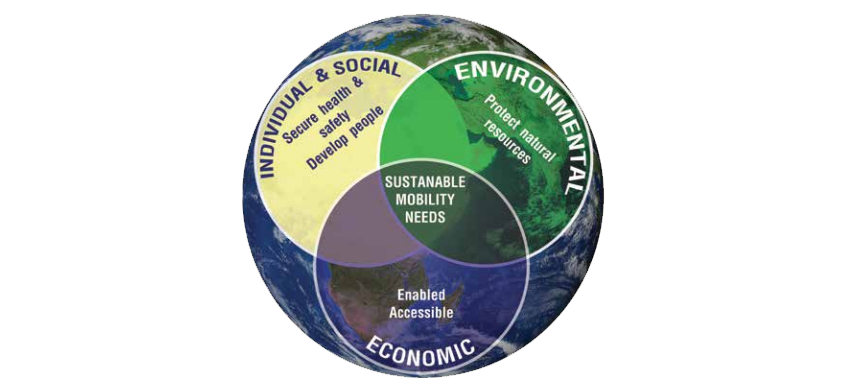

“Sustainable mobility should be safer, more efficient, more accessible, clean, connected and more enjoyable.”

Reinforcing technologies are at the heart of tire advances, particularly their weight, rolling resistance, cost, endurance and road hazard resistance.

2. Textile in Tires. Continuous Technical Progress

The casing of the tire was for many years of natural origin (cotton) and then biosourced (rayon extracted from cellulose). The rise of synthetic thermoplastics such as nylon 66 and PET has made it possible to achieve a compromise of weight and performance, which is very interesting in terms of cost. Although this rise has increased the dependence on petroleum-based materials, this evolution has reduced the development of the complex chemistry required for the rayon process.

However, the specific characteristics of rayon in terms of rigidity of extension and resistance to temperature continue to make it a preferred fiber for high performance passenger car tires, as well as for high-temperature uses in run-flat applications. With this said, the mastery of polyesters has also reduced, little by little, the use of rayon. The weight and rolling resistance of the tire carcasses are also reduced when tire models are upgraded from multi-ply casings to single-ply casings. The ability to maintain resistance to road hazards is then obtained (but not exclusively) by an increase in the cord size of the reinforcements used. However, this evolution has its limits, in particular in manufacturing.

In the field of tire summit materials the major evolution in the last thirty years has been the addition of nylon zero-degree cap plies on top of the steel belt. For the high speed indexes, this addition has made it possible to reach the speed limit requirements. For the low speed indexes it was an important improvement to the endurance of the summit of the passenger tires. This technology capitalizes on the thermosensitive nature of the nylon, which makes it possible to reconcile tire performance and manufacturing of tires.

Starting in 2000, a new textile reinforcement developed by Michelin has significantly improved high-performance tires. This product is a hybrid aramid/nylon reinforcement. At the beginning, they were reserved for a specific tire process of manufacturing without the inflation stage. Then afterwards they were applied to the conventional processes. This invention allows an increase in speed limit while reducing the mass of the summit of the tire. It is also beneficial to many other performance indicators. Its development is limited by the cost of aramid fiber.

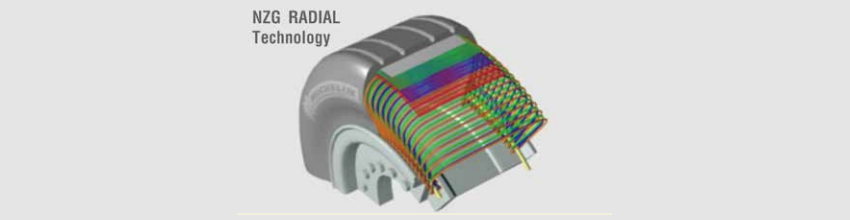

In the field of radial aircraft tires, Michelin Near Zero Growth technology, based on the replacement of nylon reinforcements by nylon aramid hybrids, has made significant progress in terms of weight, tire robustness and safety.

The use of textile reinforcements in the field of truck and bus tires remains marginal.

3. Sustainable Performance, a Major Issue

The sustainable performance of the tire is reflected in the 4 axes of the circular economy (Reuse, Reduction, Recycling, and Renewal), in particular through performance enhancement, more robustness, weight reduction and a longer life.

Textile innovation has been a major element in technical advances in passenger car tires in past years. Yet there are many other potential areas of progress which also deserve attention. On the one hand, incremental progress paths will make it possible to optimize the efficiency of the material: in particular nylon 66, PET, or the large formulation field opened up by the hybrid cable constructions.

On the other hand, breakthrough innovations will allow for progress on either tire performance or on more sustainable supply bases than the oil industry.

Thus, it may be relevant to carry out research on new fibers, allowing us to achieve the same performance as with the aramid or hybrid cables at a competitive cost.

Biosourced or recycled fibers are also interesting fields of investigation. The rise of green chemistry, the development of the use of bio-resources and the search for sustainability of access to high-performance fibers leads to a demand for fiber that respects the environment and is independent of petroleum resources. As part of Michelin's 4R approach, future reinforcements will have a reduced environmental impact. Many publications present paths to obtaining biomass monomers. It remains to be seen which will become economically viable and able to compete with the current supply chain in terms of feedstock, processing, costs and purification.

Biosourced or recycled fibers are also interesting fields of investigation. The rise of green chemistry, the development of the use of bio-resources and the search for sustainability of access to high-performance fibers leads to a demand for fiber that respects the environment and is independent of petroleum resources. As part of Michelin's 4R approach, future reinforcements will have a reduced environmental impact. Many publications present paths to obtaining biomass monomers. It remains to be seen which will become economically viable and able to compete with the current supply chain in terms of feedstock, processing, costs and purification.

Tags : kordsa,

michelin,

mobility,

performance,

product,

recycle,

reduce,

reinforcement,

reinforcer,

renewable,

reuse,

sustainability,

thereinforcer,

tire