Towards Sustainable Mobility – Trends in Tire Reinforcement

23 July 2018

Bahadır Olkun

The 21st century has been transformational from several perspectives. From our types of accommodation to the way we commute to work, and from shopping to communication we have witnessed breathtaking change in our daily lives by nature and by definition. This is also valid for the world of transportation. Connectedness, digitalization and sustainability have turned the transportation of individuals into a comprehensive concept of “mobility”.

Electrification, shared services and autonomous driving are key trends shaping the future of mobility. En route charging stations, extending the usage of ride sharing apps across the nation, and hard talks about how to regulate autonomous vehicles are becoming issues of daily life. Consumers are changing their spending patterns from “ownership” towards “service uses”. As mobility evolves, the whole transportation infrastucture as well as vehicle components are following

Car Sharing:

To keep the pace, tire technology is experiencing a rapid change as the sole element of vehicle-road interaction. As passengers turn into service users from being the owner of the vehicle, vehicle utilization rates will increase dramatically from today’s mere 5 percent level. This puts emphasis on total drivetrain reliability. Tires will play an important role.

As shared car service providers will manage a remote pool of assets, total trouble-free operation will be expected from tires. A punctured tire will upset users the most while keeping the vehicle idle until proper maintenance. This will create additional demand for run-flat tires. To withstand heat generated during run-flat driving, these tires feature body ply material with superior adhesion properties at higher temperatures. Until recently, and still extensively, rayon yarn has been used in run flat tires thanks to its excellent thermal properties. Rayon is being replaced by polyester with improved heat resistance to sustain certain adhesion at higher temperatures. This brings considerable cost improvement and promotes run-flat technology expansion on standard cars, which we call the “vehicle-free run-flat” concept.

Electric Vehicles (eV):

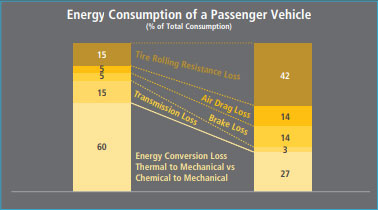

Rising environmental concerns, leaps in battery performance, and significantly lower operational costs have put eVs in strong competition with petrol cars. Miles-per-charge is still a major challenge, putting overall vehicle energy efficiency into focus. As the inefficiency of combustion is eliminated, every element, from drivetrain to air-conditioning, will be expected to function ever more efficiently. This is so valid for tires. A typical passenger car consumes 15 percent of fuel due to tire rolling resistance loss. As seen in chart 1, this portion will almost triple for an eV, increasing the demand for ultra-low rolling resistance tires.

Chart 1 -Passenger Car Energy Consumption (% of total consumption)

It is all about reducing inertia (tire weight) and the hysteresis loss of the tire structure. Apart from progress in compound technology, tire reinforcement will play an important role in both aspects. Body ply and cap ply materials with higher tenacity and smaller geometry will reduce total reinforcement weight. Hybrid cords have significant potential to secure optimized performance over a diversified range of mechanical properties. As cord geometry shrinks, less coating rubber is required, resulting in a further reduction in hysteresis loss.

Vehicle weight is another critical issue for eVs. While the specific energy (kWh/kg) of electric batteries are improving, the total weight of an eV is still 10–30 percent heavier than a petrol car depending on the required power and mileage range. Increased vehicle weight shifts demand to extra load (XL) tires. Keeping the same tire dimensions, XL tires bear higher loads at higher inflation pressures. Considering sports eVs, with UHP (Ultra High Performance) tire fitment, compelling load and speed, tire reinforcement will be forced to its limits to balance the lightweight requirements and durability. Hybrid cords of Aramid with Nylon or Polyester will have increasing potential in terms of UHP tires for eVs.

Autonomous vehicles – connected tires:

Human beings as drivers are the adaptive component of the whole vehicle system where the interpretation of road and traffic condition into driving regime is performed by the driver. Autonomous vehicles will take over the same operations with the help of peripheral sensors or trackers. Inflation pressure, tire wear level, tire temperature and even abnormal vibrations indicating a possible tire failure will be key information channeled from the connected tire.

Another aspect of autonomous vehicles is demand for continuous mobility. The occupants of a complete autonomous car will eventually become non-drivers, lacking the critical capability to replace flat tires en route. Similar to shared car operations, run-flat tires will be indispensible parts of the autonomous world.

In terms of safety, energy consumption and continuous service, tires will play a major role in the future of mobility. Environmental concerns, both public and regulative, will push users and vehicle manufacturers towards energy-efficient solutions. Reinforcement technology is expected to provide tire manufacturers with high performance and lightweight materials, not only improving vehicle energy efficiency but reducing the tire manufacturing carbon footprint as well.